Save up to 33% for years to come

Lock In The Modern CAM Stack for your shop today!

2025 is the year of AI in CNC; So here comes Toolpath's CAM Automation, to bookend smarter CNC estimates, tool recommendations, and a Kennametal partnership. Plus a price you’ll never see again.

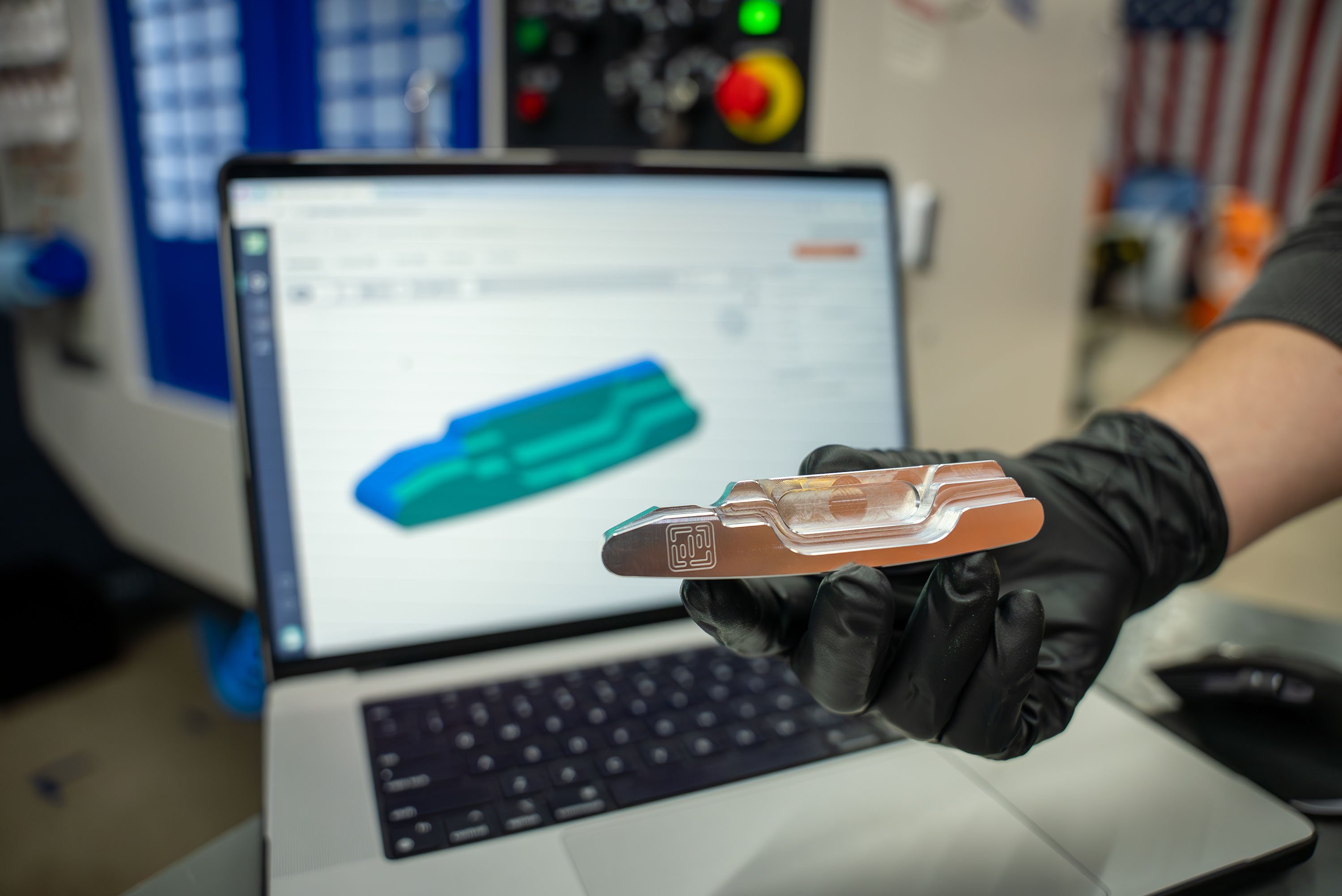

“It’s incredible how quickly Toolpath paid for itself. One job and the subscription made sense.”

“When we load models into Toolpath, we’re able to see the feedback immediately.... It’s a non-biased response to the manufacturing challenges we’re looking at.”

“I'm constantly looking for tools that make me more efficient, so I don’t necessarily have to hire more people and can still scale up. I'm planning to get more machines, and Toolpath will always be part of that. There’s no reason I’d ever get rid of them.”

Toolpath isn’t just a tool. It’s the future of CAM.

We’re shipping our biggest upgrade yet.

- CAM Automation – Native toolpath output into Autodesk Fusion

- Revamped Cut Configs – tune once, reuse everywhere

- Tool Recommendation Engine – feeds & speeds built-in

We’re teaming with the best in tooling.

- Kennametal data baked directly into Toolpath

- Starter libraries + feeds for instant programming wins

Pay Monthly

$125 USD

Normally $179 per month

Save 30% per month for the next 5 years.

Additional users are $108 per month.

Biggest Savings

Pay Yearly

$1000 USD

Normally $1500 per year

Save 33% per year for the next 3 years.

Additional users are $900 per year.

Trusted by machine shops worldwide.

Frequently Asked Questions

Subscription

-

Can I get a refund if I'm not satisfied?

If you are not satisfied with Toolpath within the first 30 days of use, you may cancel your subscription and request a full refund. -

Are there are setup fees?

No, Toolpath has no setup fees. You only pay for your subscription plan. Our partners may offer additional consulting services you may wish to take advantage of for a fee.

-

Can I choose between monthly or annual plans?

Yes, when you start your subscription from your Toolpath account, you can choose between annual or monthly plans.

If you currently have an active promo subscription, cancelling to switch to term, will void any long term benefits you may have.

-

Can I pause my subscription?

Currently, Toolpath does not offer subscription pauses, but you can cancel and resubscribe at any time.

-

What happens if I cancel my subscription?

You’ll retain access until the end of your billing cycle, but your account will deactivate afterward unless you resubscribe.

Currently, we keep your data intact, unless you ask us to delete it. In the future we may need to archive inactive accounts, but we will notify you if we end up needing to implement such a policy.

-

Does the price really stay fixed for 3 or 5 years?

Yes. Subscribe in June and your seat remains $1 000/yr through June 2028 or $125/mo through June 2030.

Support and payment

-

Do I need Kennametal tools to benefit?

No, we treat all tooling vendors equally. You choose which vendor libraries to use for tool recommendations. -

What support is included?

All subscriptions include email, chat and phone support, as well as onboarding support with the Toolpath customer success team.

Premium support plans may be available to purchase via our regional partners.

We aim to respond to all support enquiries within 1 business day.

-

How do I get support?

You can email support@toolpath.com or submit a support ticket at any time. Please provide a descriptive subject line and detail as much of the issue as you can. Screenshots and/or screen recordings help our team to get a useful response to you as soon as possible.

-

Do I need a credit card?

You don't need a credit card to start a trial with Toolpath.

We use Stripe as our payment processing platform. In some countries we may only support Credit Card payments, however, we do offer wire / ACH transfer in some countries already.

-

What payment methods do you accept?

We try to support as many payments options as possible around the world. Typically we support major credit cards and bank to bank transfers.

We use Stripe as our payment transaction platform. Please let us know if you'd like us to support additional methods for your country.

-

How am I billed for Toolpath?

You will receive a receipt for each transaction, sent to the email you used when you started your Toolpath subscription.

Unless you cancel your subscription, you will be automatically billed at the anniversary of your annual Toolpath subscription, using the same payment method you used initially.

Contact us if you would like to change your payment method.